Production Update: Overview of June and July

On May 14, Fairphone began its one-month crowdfunding campaign. At that stage, we needed at least 5,000 people to pre-order a phone in order to go into production. On June 4, we reached the goal with one week left to spare. Yay! Now, two weeks after the end of our crowdfunding campaign (sales will continue online ‚til we sell out), we finally have more substantial news to share with you about our production timeline.

We have been reeling from the results and busy trying to answer everyone’s questions. Besides planning the production, the core team went into the picturesque woods of Utrecht for a „Roadmap Session.“ There the team worked to divide responsibilities and formulate our approach now that we can take the next steps on our road map to a fairer phone. In addition, last weekend, Bas and Miquel travelled to China on separate trips to speak with – respectively, the headquarters of A’Hong in Shenzhen and the factory in Chongqing. The money from the 5,000 sold orders has now gone into a sizable payment to our production partner, to continue the development of our phone and really start production, so you can expect a lot of news from us in the coming weeks.

We have been reeling from the results and busy trying to answer everyone’s questions. Besides planning the production, the core team went into the picturesque woods of Utrecht for a „Roadmap Session.“ There the team worked to divide responsibilities and formulate our approach now that we can take the next steps on our road map to a fairer phone. In addition, last weekend, Bas and Miquel travelled to China on separate trips to speak with – respectively, the headquarters of A’Hong in Shenzhen and the factory in Chongqing. The money from the 5,000 sold orders has now gone into a sizable payment to our production partner, to continue the development of our phone and really start production, so you can expect a lot of news from us in the coming weeks.

I do want to take this opportunity to reflect on an important difficulty with how Fairphone as a company communicates what we do. Bear with me for some introspective pondering:

While our core mission is to open up systems and be transparent about our production process (relaying the nitty gritty of being a company), at the same time that product we’re making is a high-tech phone that requires the care and security deserving to our buyers who put down a considerable 325 euros.

What I’m talking about is the dilemmas and messiness that comes with engaging in our global economy – the very difficulty that we are engaging in as both a company and as everyday consumers ourselves!

Many different factors influence the timeline – and putting social values first all the time makes you re-think choices that otherwise might have been driven by deadlines that companies have toward retailers and customers. Our responsibilities lie with everyone involved in production and this will affect the timeline. We’ve had our first introduction to transcontinental production with people on the other side of the world, who speak a different language and often change positions in a company, upsetting continuity.

We’ve also been on the phone asking about delivery times of the glass for example, while hearing about strained assembly lines on the other side and realizing that pushing for earlier dates might mean longer working shifts. Getting assembly lined up means involving a ton of companies involved in sourcing and bringing together the components for our devices to a particular place at the same time.

We’ve also been on the phone asking about delivery times of the glass for example, while hearing about strained assembly lines on the other side and realizing that pushing for earlier dates might mean longer working shifts. Getting assembly lined up means involving a ton of companies involved in sourcing and bringing together the components for our devices to a particular place at the same time.

There’s a balance between being open about the production process, while at the same time giving security to you guys about the delivery date and timeline.

Rather than give you an overview of beginning till end, we’d like to take it one step at a time. Below is is an introduction of some key elements of development and production for June and July. As these items develop and the process of production unfolds, we will provide more detailed reports of the different parts over the summer. So much is happening that we need to choose what stuff to communicate. As this is your story as much as ours, please keep on asking us if there are things you want a more detailed insight into. Delivery in still very much scheduled for autumn and exact dates will be communicated first week of September. Through all this, think with us and realize all the above factors may make our schedule shift a bit, so this production schedule is not set in stone.

JUNE

- Hardware Development Ordering

For this section, we have been identifying materials, parts, and components. For example, when we tested one of the sample phones, the screen broke. Oops. We decided we needed to change the glass. As you know we will be using the most durable glass available, Dragontrail, which is sourced from Japan. But that wasn’t enough.

Because we know people will be doing crazy things with their phones and we want to give you something that can get thrown around a bit (and still work even if the protective glass breaks) we decided NOT to go for the slimmest OGS (single glass touch panel). Instead, we have separated the glass touch panel and the protective touch panel. This adds 5 grams to the weight of the phone and increases the thickness of the phone by 0.2 mm. (Added to the logbook here).

Because we know people will be doing crazy things with their phones and we want to give you something that can get thrown around a bit (and still work even if the protective glass breaks) we decided NOT to go for the slimmest OGS (single glass touch panel). Instead, we have separated the glass touch panel and the protective touch panel. This adds 5 grams to the weight of the phone and increases the thickness of the phone by 0.2 mm. (Added to the logbook here).

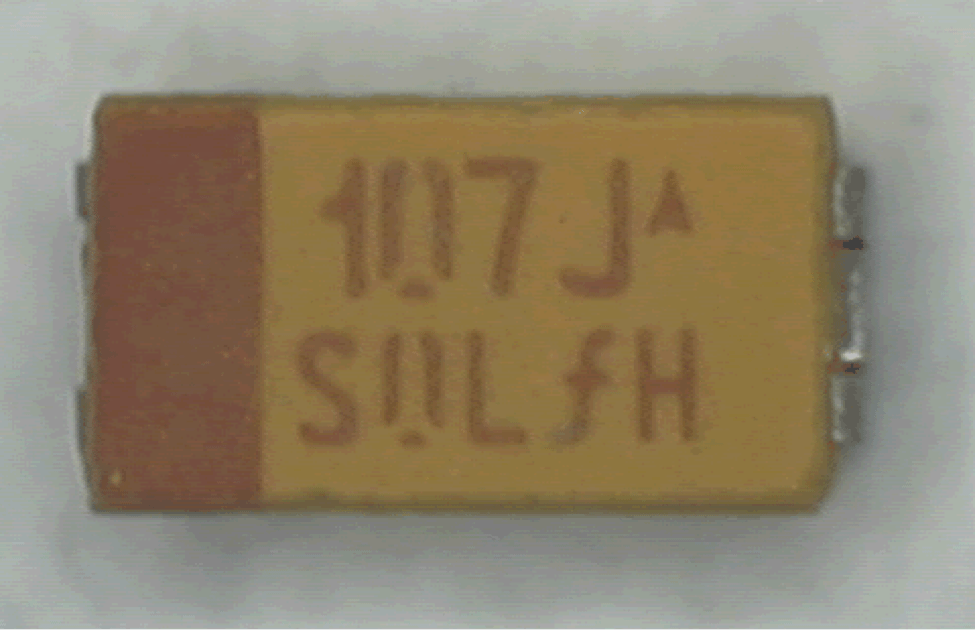

Conflict-Free Tantalum: As you know, the tantalum in your phone comes from the DRC and the capacitors (made with this tantalum) are produced in the Czech Republic by AVX. And you know what? They’ve produced them with a special „Solutions For Hope“ mark (how cool is that! see picture with „sol.f Ho“), so we can guarantee these precious materials are being used in your phone. You will see that if you get all the way to the printed circuit board. We dare you to find it in your own device!

Conflict-Free Tin: This month we will be implementing test production runs with Cookson Alpha tin, similar to the CFTI tin, which has been ordered. On the website you can keep track of where the material is – and right now as I write this, it is at the smelters. Its expected time of arrival in China is mid-July, after which the soldering paste needs to be produced. It’s crucial to get this timing right to make sure the right stuff gets into the phone.

JULY

- Social Assessment Program

The social assessment is taking place at the factory in Chongqing in July. This is the first step in our social assessment program, rather than an end point. Our program will include an audit, a remediation and corrective action plan. We have an upcoming blog dedicated to what this means, who we are working with and what our strategy is concerning the assessment program.

- Packaging

Not a minor detail! It’s an entire production track in itself. It requires similar steps to the production of a phone. Choosing the right sustainable materials, design, production partners, and other logistical considerations can be a difficult trade-off. Today, we had a helpful community member (thanks Wolfgang!) who reminded us to make the certifications on the packaging visible or European customs will send them back to China: very useful to know as the design needs to be ready by first of August.

What we already know is that we will be using a combination of recycled core material plus finishing of FSC-certified soya-based ink and under 10% VOC (volatile organic compounds). It was hard but we finally found a supplier together with A’hong.

We’ll definitely have a separate post about how to get well-designed, environmentally-friendly packaging your way.

- Software

The factory needs to finish basic tweaking of the drivers and then a software engineer will travel to Kwame and work together on final operation system image file. We are doing our best to make source codes freely available and under the GNU General Public License (GPL) – more on that from another colleague, as I’m not up-to-date on my GNU/GPL lingo!

But I’d also like to stress that Kwame is working on something much bigger. They are developing a long-term engagement with users and further development of the Fairphone OS after the first device.

A guest blog from their side will be coming to our blog in the coming weeks.

- Logistics

And last but not least Pablo (our new logistics guru) and Gabriel have been working making sure the phone is actually delivered to your doorsteps. Paramount to that is the selection of a reliable and like-minded distribution partner, with which we make the whole China-to-door process as smooth as possible.

Update on Fairphone Team

As production and our road map toward new interventions continues and we gain support from community and industry, we are streamlining services and our team is growing. With Bas, Sean and Miquel focusing on production, the team is busy taking care of daily operations. Laura has become an expert in webshop and payment systems.

Joe, Roos and myself are looking at better ways to tell our story and keep you informed through the website and (social) media channels. Robin recently joined us to make sure your questions are answered. We have Mulan, our new production manager on the Fairphone team, who will be staying in the vicinity of the factory to oversee production. Gabriel finally has some help from Pablo and together they are working on logistics, repairs and aftersales. We are in talks with an open source expert looking into connecting with developer communities at Ubuntu, Firefox, etc. Soon, we’ll need an account manager with experience in the telecoms industry to handle all the positive B2B leads now that you’ve made us a real thing. And Bibi is working on the source map and awareness raising through educational outreach and workshops. Phew. We’re busy.

Joe, Roos and myself are looking at better ways to tell our story and keep you informed through the website and (social) media channels. Robin recently joined us to make sure your questions are answered. We have Mulan, our new production manager on the Fairphone team, who will be staying in the vicinity of the factory to oversee production. Gabriel finally has some help from Pablo and together they are working on logistics, repairs and aftersales. We are in talks with an open source expert looking into connecting with developer communities at Ubuntu, Firefox, etc. Soon, we’ll need an account manager with experience in the telecoms industry to handle all the positive B2B leads now that you’ve made us a real thing. And Bibi is working on the source map and awareness raising through educational outreach and workshops. Phew. We’re busy.

But we’re also going to need several research assistants to join us and devise internal coordination with teams of experts who we need to take our next steps on the road map toward a fairer phone… and in the meantime, we need to find and move to bigger accommodation to house all these cool Fairphoners! So, we apologise for any delays. It has been all hands on deck at HQ with each team member spending a few hours a day answering your questions and feeling the pulse of our community.

It’s safe to say that your support has been awesome and just a little overwhelming. But, we’re back on track and ready to share each step of our journey. Join us!