Progress and challenges to improving working conditions with our Fairphone 2 manufacturer

When we began working with Hi-P in 2014 to produce the Fairphone 2, we made our goals for worker welfare clear: to collaboratively improve working conditions, employee engagement and employee representation. Now that we’re over a year and a half into our partnership with Hi-P, we’d like to give you an update on what has been achieved as well as the challenges still there.

Assessments show incremental progress

Part of our approach to improving working conditions includes social assessments conducted by a third party (TAOS), to identify opportunities and improvement needs at the factory and create a plan for improvement. The first assessment was carried out in October 2014.

To date, many of the identified improvements have been achieved. In terms of health and safety, all of the identified actions have been completed, including several measures to ensure appropriate exit in case of emergency and to improve safety for employees who work with certain machinery and chemicals.

Together with Hi-P we will continue monitoring the status of both health and safety and human resources conditions on a regular basis. For an overview of the latest improvements, please refer to the Hi-P social assessment report (start at page 14 for the April 2016 updates).

Human resource challenges reflect industry-wide trends

While we are making progress, certain human resource challenges have proven more difficult to tackle, specifically reducing working hours and the percentage of workers employed by a labor agency. These are common issues in the industry in China and are a reflection of wider, structural challenges.

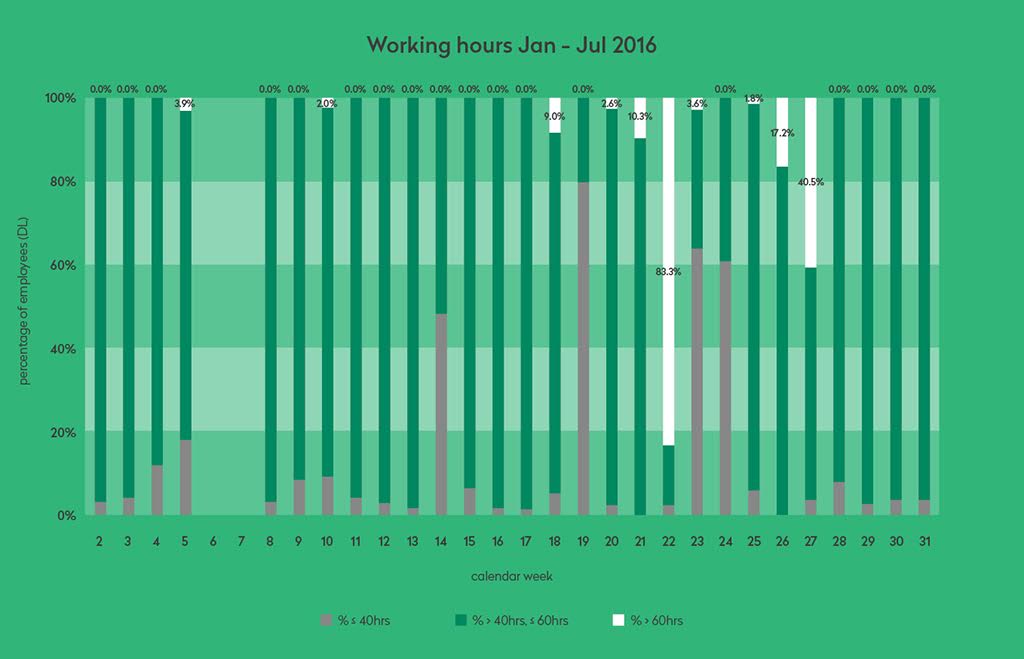

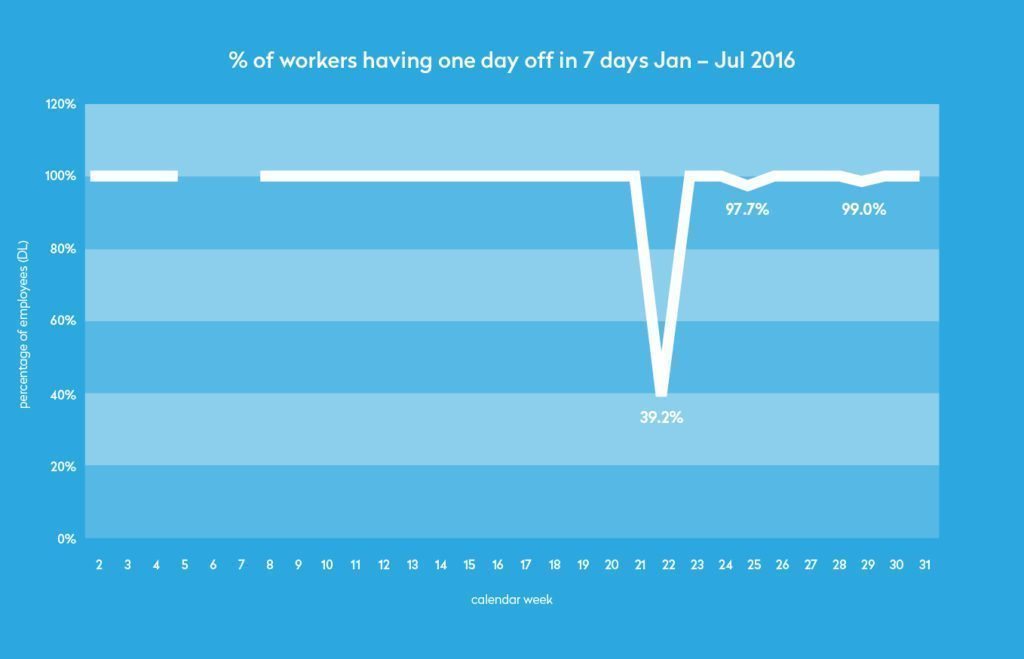

In terms of working hours, our initial target is for factory employees to work not more than 60 hours per week, as well as have at least one day off every week. Since the beginning of this year to July 2016, production employees worked fewer than 60 hours/week on average, but, as you can see in the graph below, there were also several instances where working hours exceeded 60 hours/week. The same was true of days off. While the employees generally have one day off in seven, there were also occasions where they did not get a day of rest.

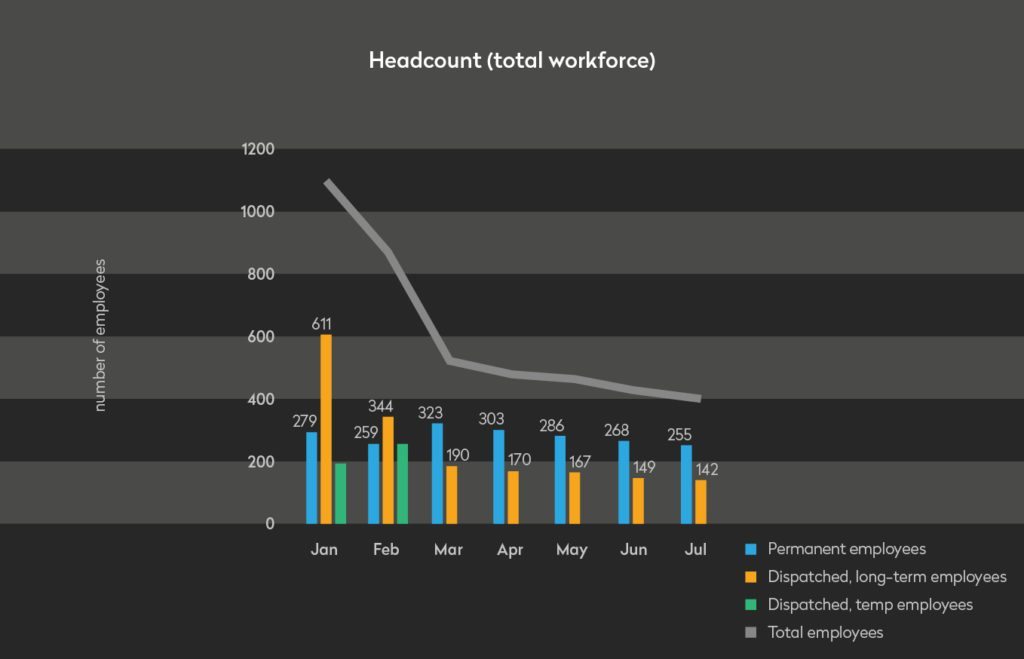

The second major challenge concerns employees working in Hi-P employed by a labor agency. In contrast to direct hires, these employees often are more vulnerable in terms of exercising their rights at the workplace, for example when it comes to representation of their interests. While Hi-P makes use of different channels to communicate with agency employees, these employees are not part of the factory’s labor union and employee representation system.

In line with the new regulations from the Chinese Ministry of Human Resources and Social Security, which went into effect in March 2016, we aim to limit the number of agency employees to 10% of the total workforce. Many Chinese manufacturers are still struggling to meet this target, including Hi-P. In April 2015, 57% Hi-P’s employees in Suzhou were agency employees. As of June this year, this figure has been reduced to 36%, in part by directly hiring some of the former agency employees.

Exploring solutions and measuring improvements

Part of the reasons for fluctuating working hours, lack of time off and a high percentage of agency employees is unstable production. With unstable production, factories sometimes prefer to rely on agency employees to be able to reduce or increase the size of the workforce more easily when needed. In order to cope with (sometimes unexpected) production peaks, employees may need to work excessive overtime. Too low production is also a challenge, as overtime constitutes an important part of employees’ salary (overtime hours are paid at a higher rate than regular hours according to local law, which is 150% of the regular wage for overtime work during regular workdays, 200% for overtime work on rest days, and 300% if overtime takes place on a holiday), and employees may decide to leave the factory when income is too low, creating a high employee turnover that costs resources (e.g. for hiring and training new employees) and can negatively affect production output and quality.

While we are only one of Hi-P’s customers, and therefore have very limited impact on the planning of the other products they manufacture, we’re working to make our own production planning and forecasting for the Fairphone 2 as accurate as possible to ensure that we are not contributing to the issues caused by unexpected peaks in production.

For example, when we were facing production delays in December, we decided not to compensate these delays with more speedy production that would have required Hi-P to hire temporary agency employees. We are lucky that our customers accepted such delays to help us achieve our goals for better working conditions (refer to this blog).

Another part of the solution to address this is increasing our sales through business channels, which will provide a more continuous and stable order pattern. For example, selling through an operator with many sales points at national or European level generates a more consistent basic demand for the Fairphone compared to direct sales through crowdfunding and direct consumer campaigns, which are more fluctuating on a monthly basis.

In addition to the monthly data on working hours and percentage of agency employees shared by Hi-P, we’re monitoring the status of these and other improvements with periodic assessments and continuous interaction with Hi-P’s management and employees on the Fairphone assembly line. Our aim is to maintain a strong, open line of communication with Hi-P to measure progress, identify potential issues and collaboratively come up with solutions.

Worker Welfare Fund planned as a pilot project

In line with our overall ambitions for employee welfare, we are in a stage of finalizing our contract with Hi-P for a Worker Welfare Fund pilot project. Our goal for the fund is to improve employee representation and engagement on workplace-related topics, as well as communication among employees, employee representatives and management. This fund is made up of a portion of each Fairphone 2 purchase.

We’re planning to roll out the Worker Welfare Fund as a pilot project for a six-month period, and expect the project agreement to be signed soon.

During the pilot phase, we will limit the scope of the Worker Welfare Fund activities to two training sessions for employees and two disbursements from the fund. The investments from the fund will be proposed by employee representatives, in consultation with their co-workers, and approved by an oversight committee including one Fairphone representative, one Hi-P employee representative and one Hi-P management representative.

We will closely monitor the impact of the Worker Welfare Fund pilot project with an employee engagement survey and independent third-party assessment at the beginning and end of the project period, and will keep you updated on our progress in the coming months.