From the factory to you: Packaging the Fairphone 2

From establishing a spare parts supply chain to developing special software features, in the past few months, we’ve been sharing lots of stories about creating the Fairphone 2 and expanding our impact with our latest phone.

One topic we haven’t touched on yet is packaging the phone – and, as you may suspect, the process is much more than just sticking a product in a box. Shipping costs, packaging materials, carbon emissions and customer experience are just a few of the elements we needed to take into account.

Getting phones and covers from Suzhou to Eindhoven

The first decision we had to make was when and where the finished phones would be packaged. Electronics companies often choose to have their final assembly factory handle the individual packaging of the completed products. However, after considering the risks and benefits, we decided that it made more sense to package the individual phones at Rhenus, our distribution center in Eindhoven, the Netherlands.

For us, this provided a number of advantages, starting with speed! At the factory in Suzhou, China, the phone can have its own production timeline processes and can be sent as soon as they are finished. And because the back covers follow a different production process, they can also be sent separately whenever they are done.

Fairphone 2 with PaperFoam® packaging, cardboard shipping box and postards

I asked Luc Bedard, our logistics king, to make a quick calculation on this and the numbers speak for themselves. The shipping of, say, 40 phones, 40 back covers and 40 batteries (which are all shipped efficiently in bulk) fills 0,30 m3 for airfreight. Shipping 40 fully packed phones including the single shipping box (which is actually very small) takes around 0,62 m3 which means that our current approach reduces the volume by more than 50%!! On top of that, we only airfreight the bare minimum, meaning all the extra materials for packaging (like user guides) are printed in the Netherlands so they never have to fly long distances. Talking about CO2 reduction is a bit tricky without having the Life Cycle Assessment (LCA) completed for Fairphone 2 yet, as emissions also heavily depend on weight. We’ll communicate more detailed information as soon as the Fairphone 2 LCA is ready.

Sustainable packaging with a positive customer experience

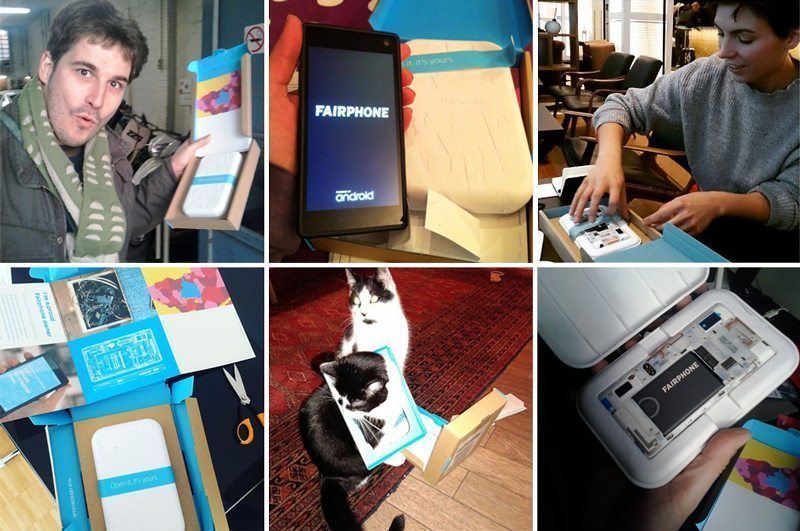

Once it was clear where we would do the final packaging, we needed to determine how it would look and function. Because the “opening experience” provides an excellent opportunity to reiterate our values and make a connection with you, our community, we wanted the packaging to be as special as the new phone we created.

Fairphone community posting their unboxing experience on social media

To guide us through the engineering process, we partnered with the packaging experts at Paxpring. Together, we started by examining the requirements and constraints mentioned above. It was also very important to us that the phone was shipped without the back cover attached. Keeping the cover detached saves valuable time during the packaging process, while at the same time giving owners a more immediate connection to their phone and how it’s made.

The selection of materials helped shape our packaging design. Because the phone packaging would be inserted into a sturdy shipping box, we had more room to play with “softer” options that provided less mechanical resistance than cardboard. After considering a variety of alternatives, we decided to use PaperFoam®. Made in the Netherlands from starch, natural fibers and water, PaperFoam® is very lightweight, as well as recyclable, compostable and biodegradable. In addition, it was easy to customize the shape of the packaging, as it is created using an energy-efficient, low-pressure injection molding technique. Plus we also thought it looked really cool!

Pairing each phone with the right color cover and putting it in this specially-designed box is the final step in the packaging process. Once everything is inside, the packaging is sealed with a strip tear-resistant Stone Paper with an inviting message to its owner: Open it, it’s yours.

Stone Paper is also an interesting material we have been playing with for a while. It is a silky, paper-like material made of calcium carbonate and a mix of non-toxic resin. The production doesn’t require any water or bleach, and it can be recycled endlessly (normal paper degrades with each recycling cycle). Stone Paper is a Cradle to Cradle (Silver) certified product. We see that it has a huge potential to reduce emissions for printed materials, but there is still low awareness on how it should be recycled (not in the paper bin). We plan to expand our use of this material when we have more space to talk about its benefits and can better educate people on proper recycling.

Packaging design and process will continue to evolve

Just like with everything else we do, the packaging design and process we’re currently using is just one step in our journey – there’s still plenty more to do and improve. Some users got mechanically damaged packages at the very beginning of our deliveries as a result of an issue related to humidity. Luckily, working with experienced partners like Paxpring allowed us to solve the issue quickly by modifying the design and storage conditions.

Furthermore, as we start to experiment with new back cover designs for the Fairphone 2 that have additional functionality, we will also need to adjust the packaging to fit these new covers.

In addition, we’re working to improve our spare parts packaging. We’ve come a long way from shipping the first spare parts to customers in ridiculously over-sized boxes, but we’re still working to optimize the packaging for what are often very tiny, but highly sensitive components.

That’s all for now folks. I’m happy to answer your questions on packaging in the chat below.