Plastics are good. As long as they are recycled.

Plastics are good.

There. We said it.

Plastics are good. As long as they are recycled properly.

A cursory internet search will show you that approximately 350 million tonnes of plastic waste is generated every year. That is a LOT of plastic. The only good thing about that figure is that there’s a lot of plastic that can be reused and recycled. At Fairphone, we have always believed in reusing and recycling whenever and wherever possible. It was in 2015 that we first started using recycled plastics in our smartphones. By 2021, we had launched the Fairphone 4 with 100% post-consumer recycled (PCR) plastics in the back cover, the first smartphone in the world to do so. The Fairphone 5 took this even further; 75% of the overall structural plastics used within is made of 100% PCR plastics. It wasn’t just smartphones. By weight, over 80% of the Fairbuds XL is made of structural plastic parts, all of which is 100% PCR plastic. Our new in-ear Fairbuds takes it even higher, where a whopping 98% of the plastics used is of the post-consumer recycled variety.

Approximately 350 million tonnes of plastic waste is generated every year. Unfortunately, a lot of it is lost to landfills, dumped in water bodies, or incinerated.

But what exactly are post-consumer recycled plastics?

Plastics can be broadly divided into two main categories. The first is the Polyethylene (PE) and Polypropylene (PP) variety, which we can broadly club as general plastics. This is what you would see in the world around you, from plastic bags and PET bottles to sticky tape and cling film. The other category is engineering plastics, which includes thermoplastic polymers like nylon, ABS (or acrylonitrile butadiene styrene), and polycarbonate (PC), among others. With smartphones (and most electronics, for that matter), engineering plastics, usually PC in most cases, is what is used because of its high impact strength and structural integrity. With Fairphone, it is even more important to ensure the original plastic sources are of the highest quality possible, because we are recycling them into complex electronic devices, and not something simpler like a plastic bucket or flower pot.

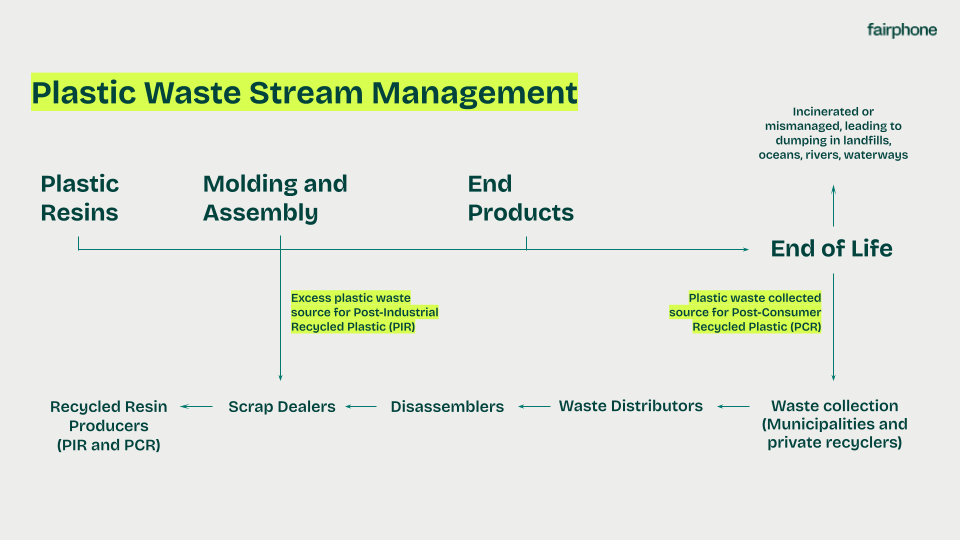

So what is pre-consumer versus post-consumer recycled plastics? Virgin plastic originally arrives at factories in the form of raw resin, where they are molded and assembled into the variety of plastic products that we use in our daily lives. What is left over from this process—such as trimmings or defective parts—is often reclaimed and reused. This is what we call pre-consumer or, to follow industry parlance, post-industrial plastic (PIR), as it never leaves the factory before being recycled.

In contrast, post-consumer recycled plastic comes from products that have already been used, discarded and collected for recycling after they reach their end of life. This is particularly meaningful, because it keeps plastic waste out of the environment, and back in circulation. Not only does this ease the demand for virgin plastic, it also closes the loop for material reuse, pushing us further towards a more sustainable, circular economy. By increasing the demand for PCR plastic, we are incentivizing the creation of better collection and recycling systems. It’s the fair thing to do, for the planet and for us.

For Fairphone products, our primary sources for PCR include large PC water bottles and jerry cans, headlights from cars, compact discs, and so on. With the Fairbuds XL, we used PC from wafer carrier boxes that can be found extensively in the semiconductor industry. These boxes are used many times over before they need to be eventually recycled, and given its high quality, it was perfect for our supply chain.

So what is the process like?

Unfortunately, a lot of plastic waste is lost to landfills or, worse, incinerated. Then there’s the problem of mismanagement, leading to plastic dumping in oceans, rivers, and other water bodies. The portion that does manage to enter recycling streams is collected by either local municipalities, or private parties, ranging from big corporations to independent waste-pickers. The collected plastic waste then makes it way to waste distributors, who then sent it to disassemblers, scrap dealers and recycled resin producers. The entire process involves disassembling, shredding, and cleaning. Eventually, the plastic mass that results from this is heated up and melted to make noodle-like strands, that are cut into raw plastic pellets.

These raw pellets then go through a compounding process, where additives are added to modify the properties of the pellets to optimize them for injection molding. These modified pellets are what we use in our manufacturing process. This entire process is anywhere between 50% to 80% less carbon-intensive than compared to creating virgin plastic. This makes perfect sense, given that you are bypassing the raw material exploitation, and the energy-intensive distillation, polymerization and granulation processes involved in making plastic out of raw petroleum.

What are some of the issues of working with PCR plastics?

The plastics that are needed for electronics manufacturing, especially smartphones, needs to meet extremely high specifications. This limits the source plastic to pure, clean waste. It is becoming more and more critical to establish more supply chains for different types of plastic waste. With virgin plastic, you can very easily control the quality of the plastic created, but with PCR, if the raw material is very dirty or heavily degraded, it can directly impact the quality of the recycled plastic. This is one of the reasons why it is harder to work with ocean plastic for making recycled plastics.

There is also the issue of plastic waste coming from multiple sources and multiple types, which makes it harder for the recycler to categorize and standardize the recycled plastic. That’s why the raw plastic waste treatment itself becomes crucial as well. The durability and longevity of the final PCR pellets depends entirely on how the compounder and recycler handle the waste itself.

Polycarbonate granules (Makrolon) – Image rights: Covestro AG

However, things have improved by leaps and bounds in the last few years within the plastic recycling space. Big polymer giants like Covestro and Sabic have made major advancements in quality control, especially when it comes to PCR plastics for smartphone manufacturing. The recyclers they work with are held to a high standard, with a major push to standardize the quality of the recycled plastics, including the colors and so on. Even five years ago, these big players would find it much harder to push PCR among electronics manufacturer, given the demands for virgin-like features such as exact color matching and absolute transparency. However, now, it isn’t as hard a sell anymore, especially with new techniques and trends like chemical recycling and PFAS-free PCR. Chemical recycling involves breaking down the original waste plastic to its molecular form, making the resultant PCR almost identical to virgin plastic. And PFAS? Most of the plastic fire-retardant additives in polycarbonate contain PFA (or per-and polyfluoroalkyl) substances. However, PFA substances are also dubbed “forever” chemicals because they are notoriously hard to break down, which means they are terrible for the environment. The EU is already making moves to ban PFAS completely, so there are already requests from many manufacturers (including Fairphone) to recyclers to make PFAS-free PCR that is still fire-retardant.

Are products made from PCR less durable than products made from virgin plastic?

We can’t speak for all products out there, but with respect to smartphones and audio products, Fairphone’s product range is held to the same rigorous testing that other electronics manufacturers have to go through. The Fairphone 5 has cleared military-grade drop tests from 1.6m and 1.8m, coming out fully intact on the other side. The Fairphone 5 has also been subjected to water jets and dust testing, earning an IP55 resistance rating for dust and moisture. This is especially impressive, given that there is zero glue used within the device. Both the Fairbuds and Fairbuds XL have also been subjected to drop tests and weatherproofing, and have also cleared them successfully. It is also worth noting that all the recycled plastics that is used in our devices is required to have cleared multiple quality control tests that are verified by third parties. At the design stage itself, if we feel that PCR plastics might be insufficient in certain areas like impact strength for example, we add extra ribs to the structural design, while considering the overall weight.

To sum it up, we can confidently say that our products are no less durable than any other electronic device out there that doesn’t use recycled plastics. In fact, combined with our modular design, long warranties and even longer support windows, they might be considered even more durable than the competition. After all, at Fairphone, we are VERY serious about designing products that are built to last.