Supporting conflict-free tungsten in Rwanda

With Fairphone 2 we continue our journey to open up the supply chain, trace materials back to the source and stimulate responsible sourcing together with our suppliers. For tin and tantalum, we continue to work with traceability initiatives that support mines in the Democratic Republic of Congo (DRC) and adjoining countries. For gold, we are progressing with our goal to integrate Fairtrade gold in our supply chain for the Printed Circuit Board (PCB) of the Fairphone 2. In this blog post, we want to share the latest developments regarding the use of tungsten in the supply chain of Fairphone 2.

What is tungsten & where is it used in the phone?

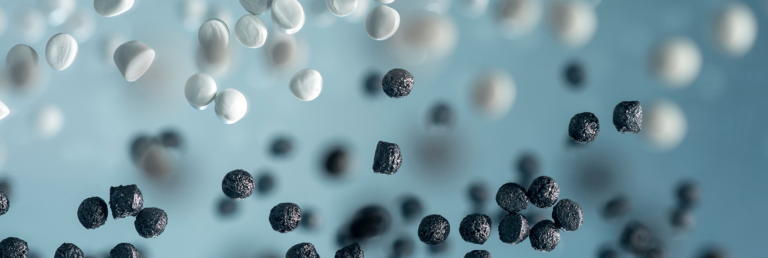

Tungsten has a very high melting point (3,422 °C, 6,192 °F) and amazing strength. This combination makes it a very suitable material to produce high speed and cutting tools such as drills and saw blades but also ammunition. In your house, you can likely find tungsten in light bulbs, the microwave and even in your ballpoint pen.

And of course, tungsten is used in electronics like our beloved smartphones. The purpose of tungsten is to make your phone vibrate when you receive a call or message, for example. More specifically, it is used to make a counterweight mechanism, which in turn is used to produce the vibration motor.

Tungsten is one of the four conflict minerals

The mining and trading of tungsten has been associated with financing local armed groups in the Democratic Republic of Congo (DRC) and adjoining countries. For this reason, tungsten is identified by a US law – the Dodd Frank Act – as a conflict mineral. Companies that are publicly listed in the US have to report on their use of the minerals tin, tantalum, tungsten and gold and the measures taken to prevent supporting conflict in the African Great Lakes Region.

Looking at the world production of tungsten, the DRC and neighboring countries only take a small share (around 2%). The highest volumes come from China, Canada and Russia. So why focus on sourcing tungsten from Rwanda? In short, the answer is because we want to transform and improve sourcing from the African Great Lakes Region, not to put it to a sudden and complete halt.

Why focus on sourcing tungsten from Rwanda? In short, we want to transform and improve sourcing from the African Great Lakes Region.

A complete ban would mean a loss of income and employment for many workers that are dependent on it. However, the increased legislative obligations and additional required paperwork for companies in some cases contributed to such unintended consequences. Because there are many alternative regions to source tungsten that are not subject to the Dodd-Frank law, the tungsten mines in the African Great Lakes Region in particular saw the international acceptance decline.

Working to reopen the tungsten trade from Rwanda

Ever since we started Fairphone, the topic of responsible mining has been a core issue for us in improving the electronics supply chain. We have been participating in several mining initiatives and regularly join round tables and industry dialogues about this topic. In May 2014, at the OECD Forum on Responsible Mineral Supply Chains in Paris, we met Steffen Schmidt, Manager International Mining of Wolfram Bergbau und Hütten AG, a tungsten mining and refining company based in Austria.

Steffen was one of the panelists in a discussion about tungsten and he presented a passionate account for reopening the trade with the African Great Lakes Region. He argued that he had been working with suppliers in the region, but that he had to put the trade to a halt due to his international clients’ demand to be “Africa-free”. Since then, the mines in the area that had been validated conflict-free had only limited outlets and buyers, mainly at dumping prices, and many mineworkers were left unemployed and pushed into the informal sector.

One of the first steps was to visit the Rwandan mines that Steffen had been in touch with. In case you want to know everything about this research trip in July 2014, look at the blog and video we published last year. The New Bugarama Mining Company mines were semi-industrial, privately-owned, and the overall infrastructure was more developed and mechanized than the artisanal mines in the region. After the trip, we continued mapping our supply chain for tungsten, starting with the vibration motor. In the meantime, Steffen continued the conversation with his customers and met with them individually to explain his position and motivation to source tungsten from Rwanda.

Our partner Wolfram Bergbau has successfully passed the audit of the Conflict-Free Smelter Program, which means their sourcing operations guarantee that the tungsten they buy from Rwanda comes from conflict-free mines.

Next steps to connect the tungsten to the Fairphone 2

To connect the tungsten from Rwanda to the actual supply chain of the Fairphone 2, several steps and possible obstacles are still ongoing, particularly regarding logistics and documentation. For example, there is special documentation required for the import and export procedures that declare the tungsten will not be used for military purposes. However, the manufacturers of the counterweights and vibration motor – Tianjia and KOTL, respectively – are enthusiastic to be part of this project and conversations are progressing smoothly to get all the arrangements in place.