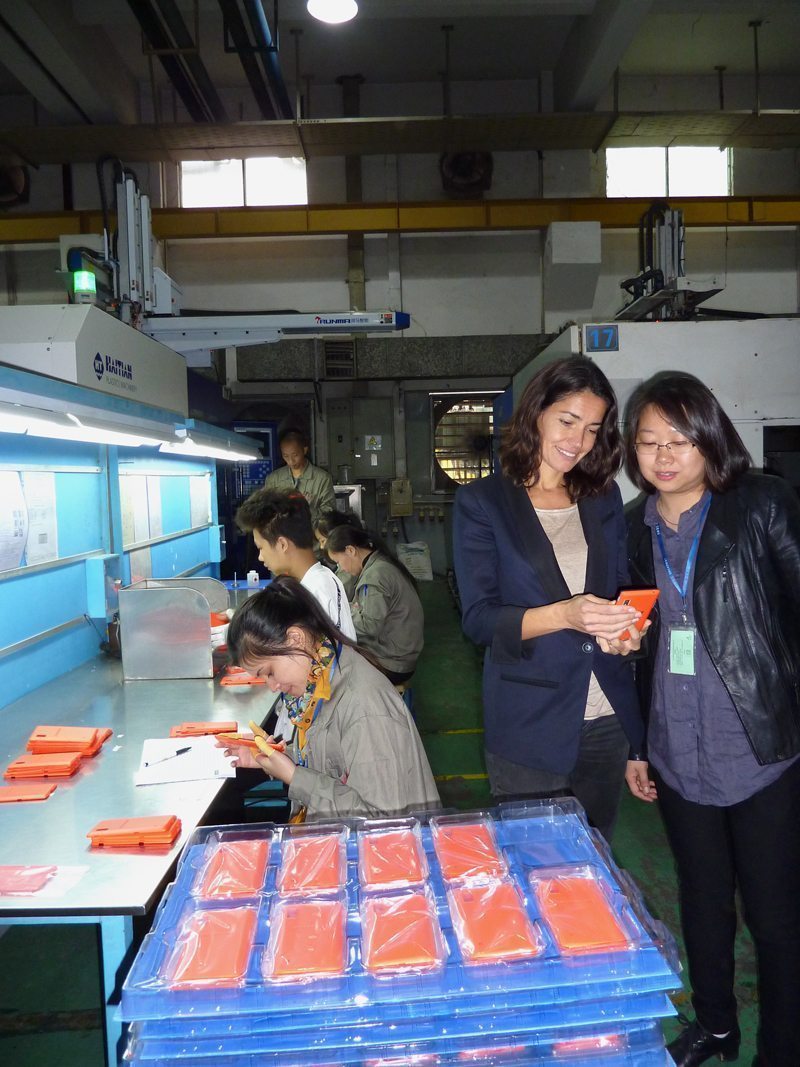

Fairphone and case producer Broadway invest in improving social performance

We would like to introduce a new partner, Broadway Group, the manufacturer of our recently launched Fairphone 2 case. Together we’re developing a project plan to further improve working conditions at their manufacturing facilities. We are receiving the help of an independent organization, the Economic Rights Institute (ERI), to carry out some of the activities. Read more about our new partnership and next steps in this project plan.

By designing and making phones, one of our high-level ambitions is to improve working conditions in the electronics sector, especially in China, where the majority of today’s manufacturing takes place. We believe that lasting change needs to happen from the inside out, based on long-term relationships, shared values and collaboration.

With the Fairphone 1, we were able to start addressing working conditions with our first-tier supplier: the final assembly factory. With the Fairphone 2, we’re working to strengthen our engagement with a greater range of suppliers – actively seeking out partners who understand what we want to accomplish and are motivated to improve their own practices.

Finding a partner that shares our values

Once we decided to create an updated cover design for the Fairphone 2, we needed to find a company to manufacture it for us. After narrowing our selection down to a few suppliers that met our quality and capability requirements, Broadway was the clear choice, scoring best on our social and environmental criteria.

Established in 2005 and headquartered in Hong Kong, Broadway Industrial Group Limited manufactures precision-machined components, primarily for the toy and consumer electronics sectors. The company has production facilities in Shenzhen (+/- 4,500 employees) and Kunshan (+/- 300 employees) in China as well as Thailand (+/- 350 employees).

A collaborative approach starts with transparency

From our first call, Broadway and Fairphone recognized the opportunity to work together on improving working conditions and reduce environmental impact. This was formalised through the Supplier Partnership Agreement signed by Broadway which outlines our shared commitment to driving social and environmental performance and included a commitment to actually co-invest in this.

Broadway has shared a variety of internal information with us, including Health and Safety procedures, chemical safety data sheets, a previous audit report (from September 2015) and existing quality, environmental and social certifications. On the human resources side, Broadway showed us their employee handbook and information about the current employee representative system – including the minutes from the quarterly meetings between employee representatives and management.

Clear goals and concrete activities in the months ahead

The project agreement outlines a concrete plan around two main topics:

- Employee/manager communication

- Use of chemicals in the production of our cases (addressing Health and Safety issues in production)

Since we would like to invest our resources directly in improvements (e.g. trainings, dialogue sessions, substitutions of chemicals) and refrain from repeating audits, the provided information gave a good basis to start with and focus on the topics mentioned above. However, to focus on these areas, a deeper assessment of the current practices is needed around the employee representative system, general working conditions and use of chemicals.

Broadway has been collaborative and reinforced their commitment to the planned activities by agreeing to split the costs of the third-party service providers 50/50. The activities will be rolled out step-by-step starting this week. The project plan includes the following goals:

Goal 1: Strengthen employee/manager dialogue to improve working conditions

Improving employee/manager communication and fostering employee dialogue at our manufacturing partners is one of Fairphone’s main goals. We believe that the employees themselves are a crucial and untapped resource for identifying issues and suggesting changes that can positively impact their working environment. To improve communication, uncover challenges and find tangible solutions, we will work with Broadway to:

- Assess the existing employee representative system

- Conduct an employee satisfaction survey with 80-100 employees to get a wider understanding of the main issues

- Host dialogue sessions with around 40 employees and managers to uncover concerns and define improvements and priorities

- Provide training to employee representatives, employee volunteers and management (on how to find compromises and how to collect opinions from employees)

- Lead employee/worker dialogue sessions to address the identified topics

These activities will be carried out with assistance from the Economic Rights Institute (ERI), an independent Hong Kong-based organization specialized in strengthening worker/management dialogue in China. Fairphone has worked with ERI in the past to help us implement the Worker Welfare Fund with our production partner for the Fairphone 1.

As part of our goal to make a positive impact on working conditions, we want to support our partners to improve their health and safety measures. Specifically, we want to protect employees from accidents and illnesses caused by hazardous/toxic substances. (Read more on Fairphone’s approach to hazardous/toxic substances.)

To complete the assessment, we plan to do an initial third party assessment. Dependent on the outcome of the assessment, Fairphone and Broadway will agree which steps need to be taken, if needed, for safer chemical handling and/or substitution of chemicals.

Building the foundations for a mutually beneficial relationship

Our approach to supplier engagement is continually developing based on each new partner collaboration. Therefore, every new project we undertake is a learning process for both ourselves and our partners. What remains consistent is our belief that these activities can provide the foundation for a long-term business relationship and lasting improvements. We’ll keep you updated as we move further with the goals of our project plan.