Zero Exposure: This is how we make factories fairer

It’s funny when you think about it. In the 1940s, cigarette companies would actively use doctors in their advertising campaigns, leading to such classics as ‘More doctors smoke Camels’. If you went by the ads, cigarettes were physician-tested and approved. Of course, today, these things won’t fly anymore, thanks to strict regulations in place to make sure you, as a consumer, know just how safe (or dangerous) the products you use are. This is especially true in Europe, with numerous laws and consumer protection bodies acting as watchdogs to protect you and your health.

HERE’S WHAT ISN’T FUNNY

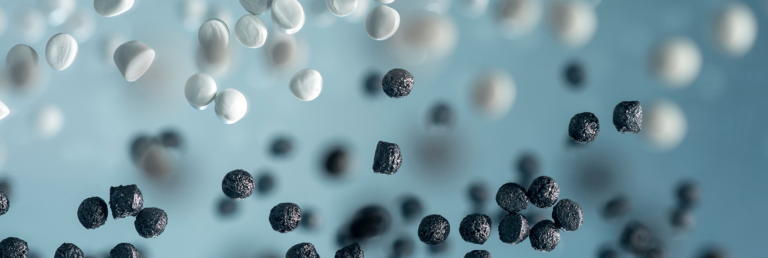

What isn’t funny is that the factories where your products are made are still not held to the same standards. The people who toil endless hours in these buildings run the risk of exposure. There are numerous hazardous chemicals like cleaners and solvents that are used during the manufacturing process, but don’t end up in the final product. The irresponsible use of toxic chemicals can be directly linked to the numerous cases of occupational poisoning, resulting in higher incidences of cancer, reproductive damage, birth defects, other serious illnesses, and even death. The global electronics industry is culpable as well, with not the best track record when it comes to chemical management and worker safety. (For a comprehensive list of case studies and news articles linked to this, we highly recommend Good Electronics. You can also check out this eye-opening documentary on Vimeo.)

SO WHAT’S FAIRPHONE DOING ABOUT THIS?

So how do we, at Fairphone, tackle this issue? How do we ensure that the people working in our supply chain are not falling sick? How do we prevent them from getting exposed to hazardous chemicals while working on our products?

Since 2017, we have been working alongside other electronics manufacturers, chemical companies, human rights activists, and NGOs, to address this issue, coming together to form the Clean Electronics Production Network (CEPN). The network was created to understand, and ultimately eliminate, the risks that come with chemical exposure. Over the years, CEPN has identified which chemicals are the most dangerous, placing them on top of our priority list. It has also helped to map the use of these chemicals, find alternatives, figure out tools and equipment for better chemical management, and build a safety culture where workers are consulted and informed, and actively participating in the decision-making process.

TOWARDS ZERO EXPOSURE

All of these efforts eventually crystallized into the Towards Zero Exposure commitment program, a commitment to protect workers and roll out adequate methods to keep them safe throughout the supply chain. Currently, there are four leading electronics manufacturers who have signed up to the program, with Fairphone being a founding signatory. Fairphone has always prioritized worker safety; it is why we have always maintained a Restricted Substances List (RSL) that is shared with all our suppliers. Some of our key activities as part of the program include:

- We ensure none of the priority chemicals identified by the CEPN are used at the final assembly factories of the Fairphone 4 and 5, the Fairbuds and the Fairbuds XL.

- We involve direct and key sub-suppliers to employ the CEPN’s Process Chemical Data Collection (PCDC) tool on our use of priority chemicals, with data representing over 80% of our supply chain spend. All the data collected, as well as other documents of our suppliers, are thoroughly vetted internally at Fairphone.

- We have also actively engaged with the factory who works on the final assembly of our smartphones to make sure their safety committee meets all of CEPN’s best practices requirements. This ensures workers are educated about, and fully involved in, enhancing workplace safety.

As of today, Fairphone bans the use of 28 chemical families in our manufacturing process to protect the health and safety of our workers. None of the final assembly manufacturers of the smartphones and audio products use these 28 chemicals in manufacturing, and we will continue to map further in the supply chain. And as per the latest annual report of the Towards Zero Exposure program, we’re proud to be the first electronics company to begin work on eliminating CEPN’s second round of priority chemicals.

Of course, absolute zero exposure can only be a reality if more and more companies sign up and incentivize their suppliers and sub-suppliers to follow through. So if you’re someone who works in the electronics industry, or know someone who does, enroll your organization for the Towards Zero Exposure program asap. It’s the fair thing to do.