Partnership beyond the first tier: social impact with sub-supplier GSN

Fairphone 2 allows greater opportunities to build relationships and programs beyond first tier suppliers since we created our own custom design. Owning our design allows us to select more of our phone’s components, as well as reach out to and build relationships with individual sub-suppliers that share our values for creating positive social and environmental impact.

In the coming months, we’ll be introducing you to some of the production partners that we’re collaborating with – not only to provide materials and components, but also to devise and implement projects that expand the movement for fairer electronics.

Supplying connectors for the Fairphone 2

Actually, we didn’t find the company we’d like to introduce you to in this blog – they found us! Connector manufacturer GSN has been working to integrate social impact into their business. In early 2013, as the company was beginning to implement this strategy, GSN CEO Frank Püschel got in touch with us to explain what his company was trying to achieve and ask if there was a possibility to work with Fairphone, having in mind a partnership that could both advance GSN’s transformation road map and support Fairphone’s value proposition.

Thanks to Frank’s proposal, we took a closer look at what GSN was doing, and realized that there were many areas where our views aligned, especially with regard to working conditions and employee wellbeing. But beyond shared values, we had to be sure that they could actually supply materials that we could use for the Fairphone 2.

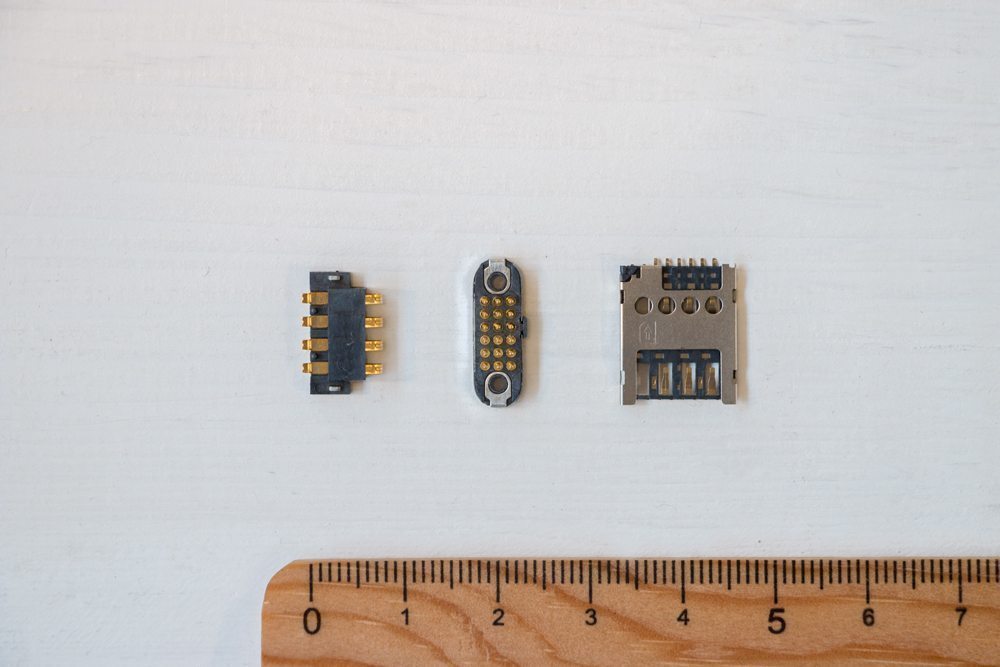

GSN produces a number of connectors for Fairphone 2, including fully customized module connectors that are an integral part of the design of the phone. They allow the user to easily open up and change the individual modules quickly and reliably.

GSN produces connectors and cables for a range of international clients, primarily in the automotive and consumer electronics sectors. We needed a wide range of connectors in this product, ranging from standard off-the-shelf parts (connectors for the battery, the SIM card sockets, the headset connector and so on) to fully customized module connectors. The latter enable the modules of the Fairphone 2 to be connected to the main circuit board and are therefore an integral part of the design of the phone. They allow the user to easily open up and change the individual modules quickly and reliably. To produce these customized, very fine assemblies, GSN developed a technique to handle the really small spring contacts before and during the assembly of the connectors.

Piloting more responsible practices

GSN combines business and social targets, for example by devoting shares of the annual dividend to reinvest in social activities. Two-thirds of the annual dividend goes to social activities inside and outside the company. The remaining one-third is the shareholders’ maximum share of monetary dividend. Beyond a monetary dividend, GSN is currently working on a system to evaluate a non-monetary “social dividend” in terms of social impact achieved. By embedding this approach into the company’s business strategy, GSN is attempting to create an example for a more ethical and sustainable business conduct in the industry.

GSN operates three manufacturing locations in Shenzhen, China. One of them is GSN’s ‘Fair-Trade Pilot Center’, where the connectors for Fairphone 2 are being produced. This is a small manufacturing facility that is pioneering activities with the aim of increasing the social wellbeing of its workforce. Once these initiatives are well established and effective, GSN plans to implement them at their larger production facilities as well.

GSN operates a ‘Fair-Trade Pilot Center’, where the connectors for Fairphone 2 are being produced. This is a small manufacturing facility that is pioneering activities with the aim of increasing the social wellbeing of its workforce.

Currently, the pilot center employs 33 people, 21 of which are working in production. The employees have recently elected four representatives in an anonymous vote to help voice the needs and concerns of the workforce to the management. Besides employee representation, GSN has introduced a number of other innovative programs at their pilot center. As many Chinese factory workers originally come from other regions of the country, employees who have worked at the company for at least a year have the opportunity to take an additional 10 days of paid leave a year (2 trips of 5 days each) to return home to see their children. GSN also reimburses 50% of the employee’s travel expenses for these trips. In addition, the company covers the entire social insurance contribution, which in China is generally split between the employer and employee. Finally, GSN makes English lessons available to all employees during working hours and provides fresh fruit every day.

Partnership starts with a social assessment

Together we aim to pilot approaches to create positive social impact at the workplace and inspire the industry to act in a more responsible way. As with other production partners, we have started this journey with an independent social assessment at the factory, followed by a joint improvement process over the past months. The goal of this assessment is to understand the current conditions with regards to applicable labor law and best practices. Importantly, it is also a baseline to start working together on improvements, as well as to identify areas for innovation and future cooperation.

The goal of an independent social assessment is to understand the current conditions with regards to applicable labor law and best practices.

On 4 June 2015, our partner TAOS visited GSN’s pilot center to complete the initial assessment, consisting of a factory walk-through, document reviews and interviews with 22 employees, including the four employee representatives. GSN was very receptive to the process and viewed it as “a highly appreciated milestone in GSN’s transformation road map” (CEO Frank Püschel). The assessment uncovered a few areas of improvement related to company policies, HR practices and health and safety issues.

During the past months, we’ve been working together on improvements, most of which have already been completed. For instance, it became clear during the assessment that overtime pay had been calculated incorrectly. GSN was quick to remediate this situation by sending a personal letter of apology to all the individuals who were affected, and issuing retroactive payment, along with 8% interest as a best practice. Other examples include conducting fire drills and training selected personnel in first aid. If you are curious to learn more, you can download the GSN improvement plan.

While most of the employees interviewed liked the English classes, they also mentioned that they have difficulties learning the language. Based on this feedback, GSN has been working on better tailoring the English classes to the employees’ needs.

Next steps and long-term goals

Based on the results of the assessment as well as the goals the company has set for itself, there are still a number of improvements that GSN hopes to implement in the coming period, some of which require a longer-term approach. Earlier this year, GSN hired a full-time global corporate responsibility manager and a local corporate responsibility manager based in Shenzhen to assist in introducing these changes.

For example, based on a proposal made by the employee representatives, GSN aims to provide equal conditions for production and managerial employees, and has already started by introducing a unified monthly pay date for both groups, and offering everyone 15 days of paid leave per year. Additional measures are also being considered to provide equal opportunities for individual growth, including introducing standard performance indicators, performance-based raises and training options.

A number of additional measures are being considered to provide equal opportunities for individual growth, including introducing standard performance indicators, performance-based raises and training options.

Finally, a continuous challenge is balancing working hours over the course of the business cycle, ensuring that they do not exceed 60 hours per week during busy seasons and providing enough work to guarantee job stability during low seasons. Besides improving work scheduling and monitoring of overtime, GSN hopes to reduce working hours by better defining job roles and responsibilities as well as internal procedures to optimize productivity. During times of low production, employees are encouraged to take their paid annual leave to maintain a stable workload. At the same time, GSN plans to design a progressive remuneration system (salary and non-financial benefits) that can support workers in achieving a living wage standard in the future.

In addition to the improvements already mentioned, we’re currently working with GSN to identify a longer- term joint project to increase the positive social impact in our value chain. Examples might include additional initiatives for employee wellbeing, and GSN is also interested in exploring the use of more responsibly mined gold and conflict-free tin. We’re just at the beginning of our relationship with GSN, and are excited to see where it will lead in the long term. As soon as we have additional details to share, you’ll be the first to know.