Scaling up Fairtrade gold sourcing in our supply chain

Every material in your smartphone has its own story to tell. Since Fairphone began, we’ve been helping to shed light on those stories, by mapping our supply chain, tracking what’s used in our products and making step-by-step improvements. Gold is one of our key focus materials – an essential, but problematic material for the electronics industry.

Gold’s scarcity and unique properties make it one of the world’s most valuable metals

But gold mining poses a wide variety of social and environmental challenges, such as land disputes, unfair pricing, unsafe working conditions, child labor and pollution. In the transition towards a circular economy, it is key to decrease our dependence on mining. At this moment, however, 75% of the world’s gold supply is mined, with 90% of the miners working in artisanal mines. That means an estimated 15 to 20 million people relying on artisanal gold for their daily income and livelihoods. As it will take the world decades – if not more – to fully meet the demand for gold through recycling, the industry will stay heavily reliant on mined gold. So while we need to put efforts into increasing recycling, such as through our take-back programs for old electronics, it is critical to ensure the mining sector improves and that people work under humane conditions and/or are supported in a transition towards other, more sustainable livelihoods.

Our first step in integrating Fairtrade gold in our Fairphone 2 supply chain

Our journey to include responsible gold in our supply chain started with the Fairphone 2. With the help of our partners AT&S (our printed circuit board supplier),Valcambi (one of the world’s largest precious metal refiners) and Fairtrade, we set up our first pilot Fairtrade gold supply chain. Fairtrade is an organization that monitors and ensures higher social and environmental standards through certification, producer support, programs and advocacy.

Tracing the gold used in the Fairphone 2.

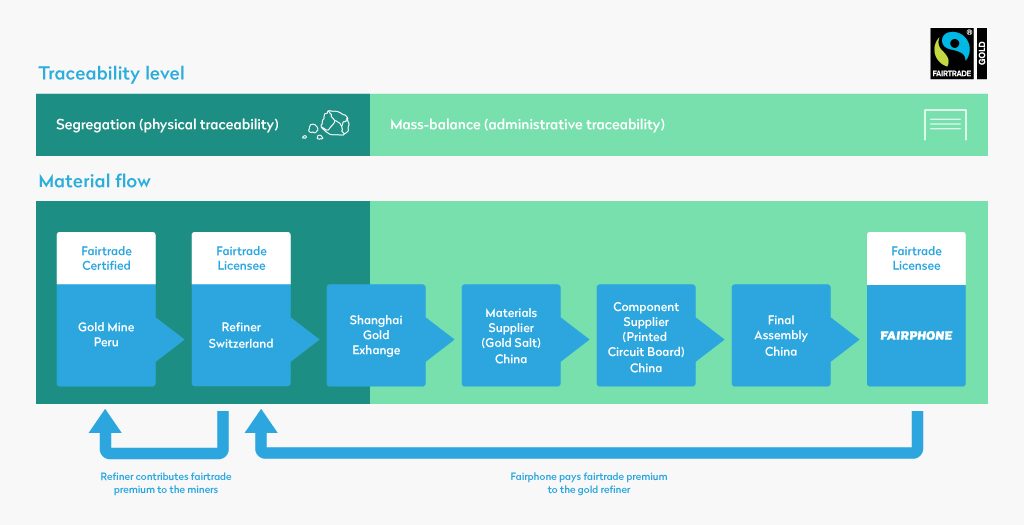

In order to bring the Fairtrade certified gold from the mine to the market, we used the Fairtrade mass-balance sourcing model. This means gold mined in a more responsible fashion from the certified mine remains segregated until leaving the refinery, allowing it to be audited for its Fairtrade license. We then bought this Fairtrade gold from the refiner, and shipped the gold amount needed for the production of the Fairphone 2 directly to our component manufacturer. The certified gold was then mixed (mass balanced) with non-certified gold sourced by the component manufacturer to supply a larger spectrum of clients.

While this means the Fairtrade gold doesn’t necessarily end up in your specific product, mass-balancing the gold is critical. Using certified gold that is fully segregated from mine to mobile phone incurs significant operational and logistical costs along the entire supply chain. Using mass balance is necessary to keep costs down to allow the reach and on-the-ground impact of the program to expand over time. And more importantly, it still delivers the same benefits and positive impact for the miners. (For additional information about traceability and related models, you can read this detailed report published by the United Nations Global Compact.

Scaling up responsible gold sourcing with the Fairphone 3

Ensuring that the innovations we pilot are scalable is key to our mission: the more they can be replicated throughout the industry, the more positive impact will be generated. In order to ensure this gold sourcing model is scalable enough for wider industry adaptation, we realized that we needed to mass balance the gold even earlier in the supply chain: right after leaving the refinery. For Fairphone to buy the gold directly from the refiner and subsequently shipping the gold straight to component suppliers changed the supply chain too much: it was too complicated, more costly and operationally inefficient as all suppliers based in China source through the Shanghai Gold Exchange (SGE).

Thanks to extensive discussion and creative thinking with Fairtrade and Valcambi, as well as our supply chain partners, we developed a model we believe fits the average electronics supply chain:

Our scalable Fairtrade gold sourcing model.

By mass balancing the gold earlier in the supply chain and paying the premium directly to the refinery but allowing the Fairtrade gold to be sold and shipped as ‘regular’ gold through the exchange, we are able to increase the amount of Fairtrade gold we are buying, connecting it to even more component manufacturers sourcing their gold through the SGE, and ultimately impacting even more people!

Join us in building a fairer future together

It is entirely possible to grow the amount of Fairtrade gold sourced worldwide in the coming years. For the Fairphone 3, we currently have three suppliers sourcing our Fairtrade gold through the SGE. Previously, we have bought an average of 100 grams of Fairtrade gold per year, but our new, scalable approach means that we now aim to grow that amount to one kilogram of Fairtrade gold per year (in fact, we have already bought 500g in the first half of 2019). And with this improved scalable model, it also becomes much easier for other industry players to source Fairtrade gold as well.

Ensuring demand, however, is only one side of the spectrum; ensuring the supply of certified gold keeps up with increased demand is also vital. For this to happen, the sector needs extensive and thoughtful investment to get more artisanal gold mines up to the standard of Fairtrade mining practices. That’s why we are actively working with our partners Fairtrade, Solidaridad, UNICEF, The Impact Facility, Philips and Hivos/ Stop Child Labour, to support miners in improving mining practices in East Africa, specifically in Uganda. By working together, it’s possible to create long-term improvements across the entire industry.

With more industry players sourcing through this model, a larger group of miners will benefit. Miners will see that there is a worthwhile market for responsibly produced gold. We therefore warmly welcome any other electronics manufacturer interested in sourcing Fairtrade gold to contact us >