How we made our fairest battery yet for the Fairphone 5

We are very proud that with the Fairphone 5, we have also launched our fairest battery yet. Possibly even the fairest smartphone battery on the market – at least based on the information that is publicly available.

Batteries are a crucial part of the global transition to renewable energy. That is also why battery manufacturing and the connected material supply chains have been in the spotlight increasingly in recent years. A plethora of environmental, social and governance (ESG) red flags are popping up in battery value chains, including pollution of air, water and soil, greenhouse gas emissions, negative impacts on biodiversity, dangerous and unfair labor conditions, and a lack of transparency. We wanted to address that with our Fairphone 5 battery.

When we looked into what our industry is currently doing on smartphone batteries, we found that most companies are focussed squarely on the battery’s charging capacities, such as increasing charging cycles or enabling fast charging. We could not find much on how our industry is addressing social and environmental issues in battery chains, let alone on how benefits can be created for people and planet. But we knew that our users actually care about this. This is why we set out to create a fairer battery for the Fairphone 5.

The Vision and Approach

At the beginning, we sat together to define what we wanted to improve from the Fairphone 4 battery, coming up with a set of benchmarks that encompass the many factors that need to be part of a fair battery across its whole life cycle. We broke this long-term vision down into a list of targets, aiming to achieve them by the time of the Fairphone 5 launch. We can now proudly say we did.

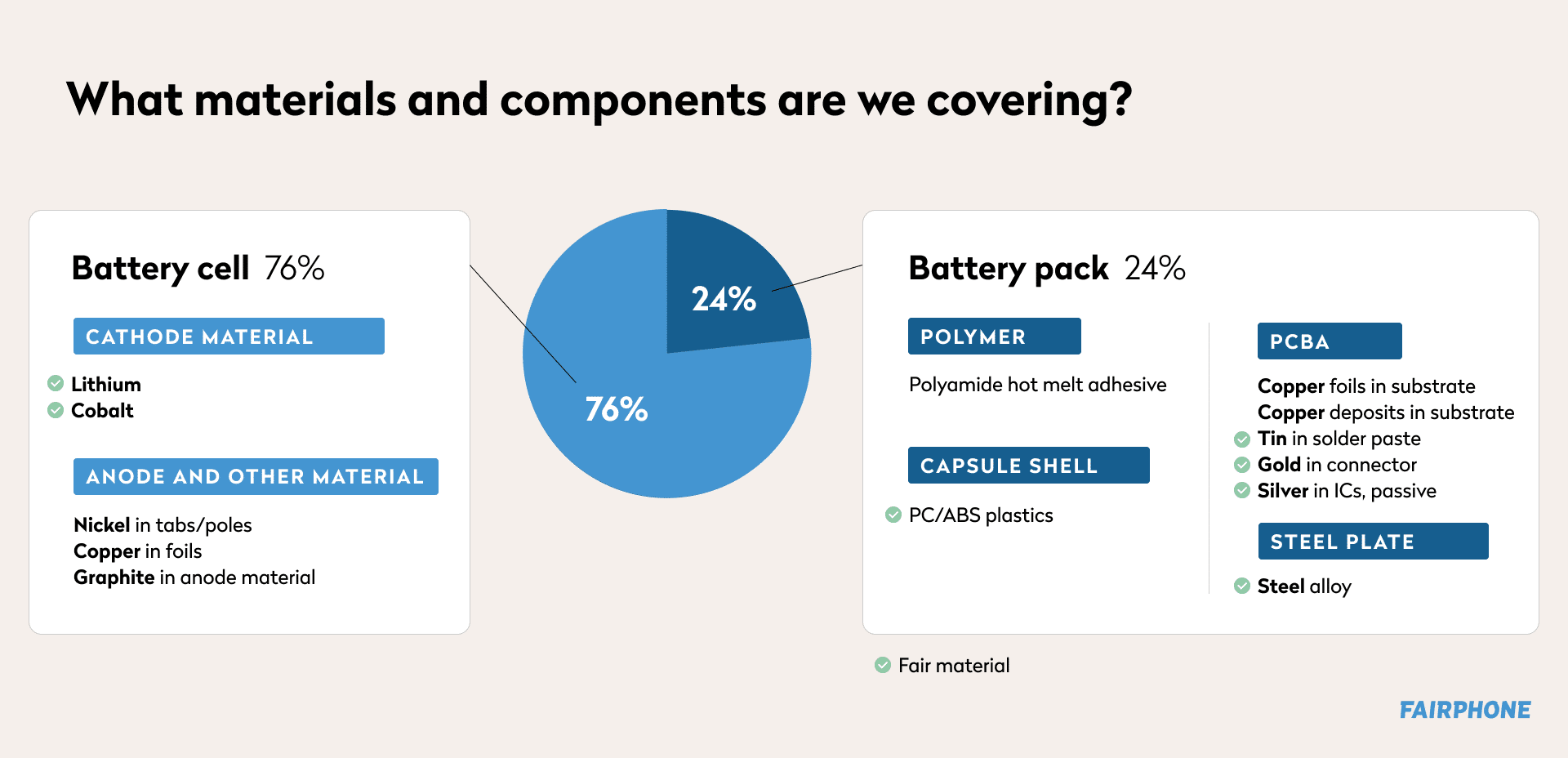

- Materials: The battery cell and battery pack contain eight of our 14 focus materials. We managed to work on six of them (plus steel) to make sure they come from fairer sources or create positive impact for miners and their communities:

- 100% lithium from a mine site assessed against the IRMA standard

- 75% post-consumer recycled plastics in battery frame

- 100% recycled tin solder paste

- 80% recycled steel (not a focus material)

- Fairtrade gold in the supply chain

- 100% cobalt credits

- 100% silver Fairmined credits

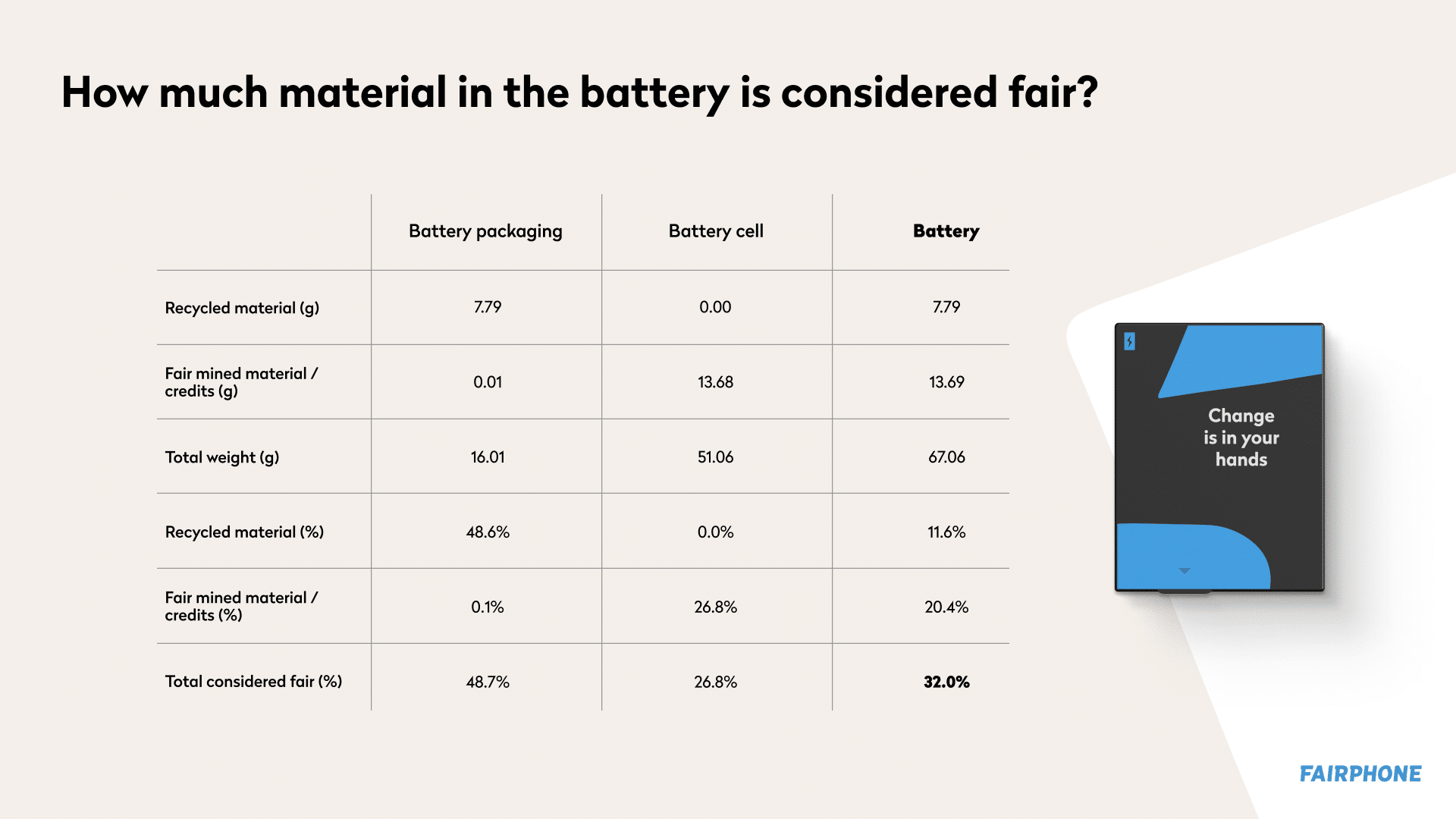

Despite the complexity of battery composition, we made nearly one-third of the battery weight “fair”, meaning almost a third of the materials came from fairer sources, or created positive impacts for miners and their communities. This also had to be done without compromising on the battery’s capacity (4200mAh), charging speed or overall longevity.

- Manufacturing:

The battery testing labs at the factory

-

- Our battery pack supplier is part of our fair factories program. We collaborate with them to provide a living wage bonus to the workers assembling the battery, at a rate of $0.09 per battery. We also work with the battery pack manufacturer to implement worker surveys and establish continuous improvement plans.

- On top of that, our battery pack supplier committed to CO2 reduction targets in line with international standards (the Science Based Targets Initiative), and are planning to assemble the Fairphone 5 battery with 100% renewable energy from 2024 onwards.

- During the program, the change we saw in our battery pack supplier was impressive. They rapidly grew their knowledge and actively committed to these impact goals. We won’t say this is 100% because of Fairphone—of course, there are other customer’s requests, and general awareness about the climate crisis is increasing—but we are happy to see the progress.

- Use: Like with all the Fairphone models before, the Fairphone 5 battery is also easily replaceable, supporting our vision of modularity, repairability and longevity. It also supports fast charging and has a capacity of a minimum of 800 charging cycles.

- End-of-life: The entire Fairphone 5 is electronic waste (or e-waste) neutral. This also includes the battery.

But how exactly did we go about achieving all of this?

The first step was selecting battery suppliers for the Fairphone 5 that were aligned with our vision and mission, and were able to work with us on achieving these targets. We wanted to work with a battery cell supplier that can make sure that lithium is from IRMA assessed mine sites. This was not easy, because the supply chain is long, and there are often concerns around business confidentiality.

Meeting the refiner in Sichuan, discussing the current technology available and challenges with the lithium raw material market.

Of course, there are a lot of other factors that play into selecting suppliers, especially since the battery also needs to comply with very high technical and quality standards. By closely working with our quality, engineering and supply chain teams, we were able to select suppliers that could not only fit the expectation on quality, but also deliver on impact.

Of course, this was only the beginning. We now needed to engage and work closely with the selected suppliers based on a relationship of trust and transparency. Our product and engineering team worked closely with our final assembly partner as well as the battery suppliers, to ensure the integration of fair materials on top of dealing with the performance, quality, cost, and certifications needs. At the same time, Fairphone’s impact innovation team worked closely with the suppliers on impact agendas for fairer factories, reducing carbon emissions, material due diligence, and providing support and guidance, depending on the level of maturity of each supplier.

Our Lithium Chain

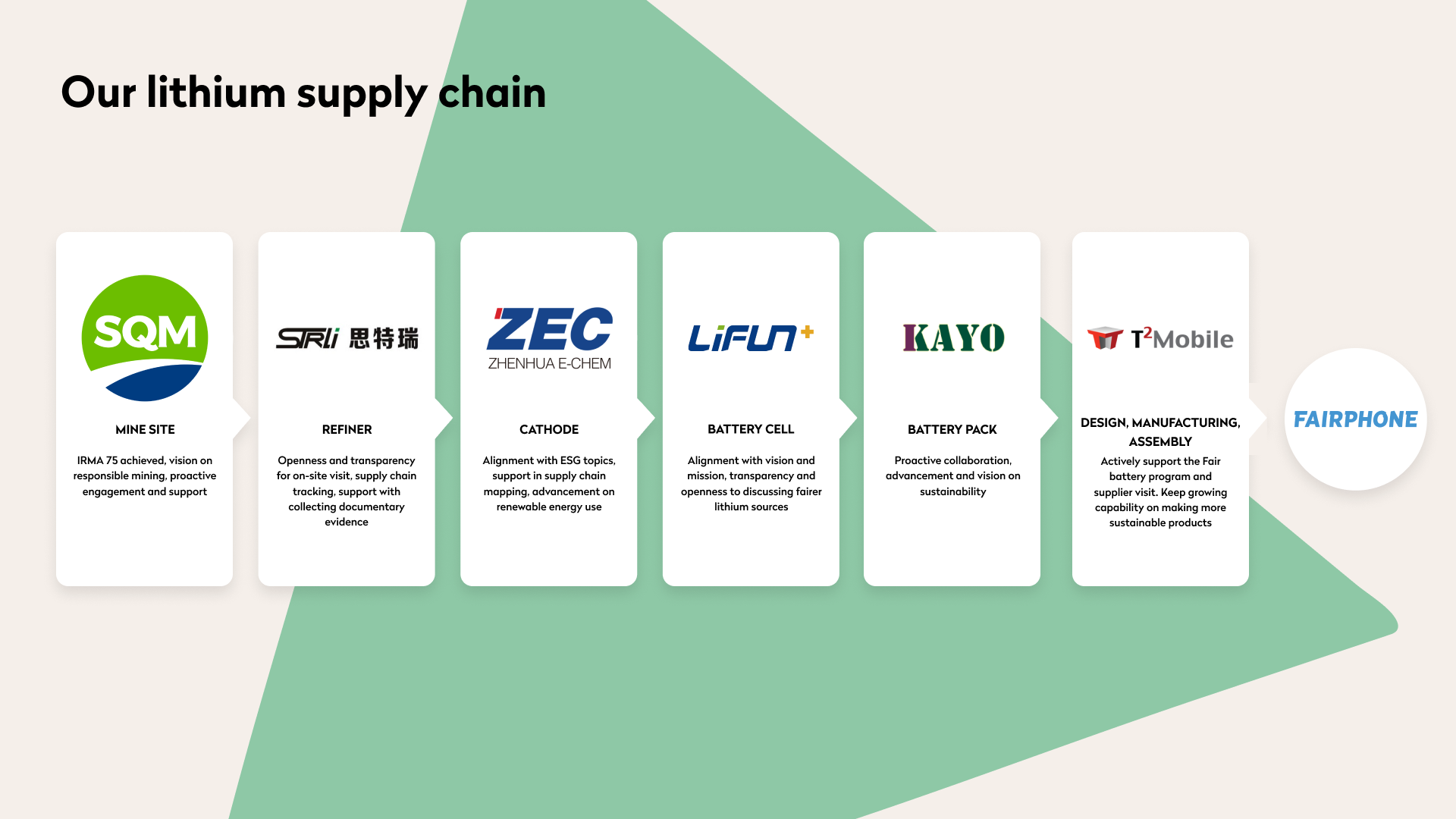

We mapped our entire lithium supply chain and engaged directly with each (sub-)supplier—from our final assembly manufacturer to the battery packaging manufacturer, the cell manufacturer, the cathode material provider, the refiner, and ultimately, the mine site. Except for the mine site, we also visited all these sub-supplier factories in person, to establish personal contact, understand their business and operations, and of course to also collect documentation and evidence on the chain of custody.

This means that we could guarantee the lithium we use in our batteries come from a mine that was one of the first to be audited against the IRMA Standard for Responsible Mining. This is the strongest, most encompassing and transparent global standard for industrial mining, which was developed and is governed equally by civil society, communities, labor unions, and the private sector. The mine site was independently assessed to determine how well it performs with respect to fair labor and terms of work, health and safety of workers and communities, prevent pollution of air, water and soil, protect biodiversity and obtain free, prior and informed consent from indigenous peoples, amongst many other requirements. IRMA assessments are not pass-fail: independent auditors assign an achievement level of IRMA Transparency: IRMA 50, IRMA 75, or IRMA 100.

We are very happy with the results we achieved in partnership with our final assembly partner and battery suppliers. But for us, this is just the start. In the coming years, we want to push further on creating even fairer batteries, and we want to see the industry joining us in this endeavor. Because we know that smartphone users care about it!